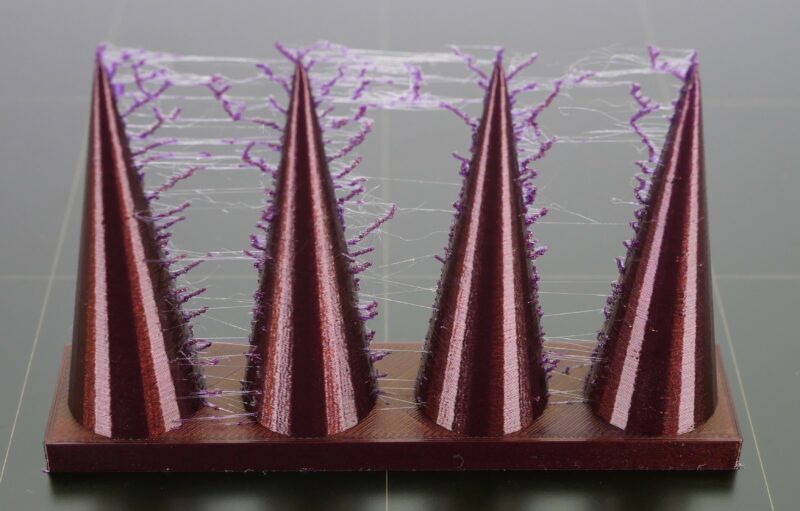

"Stringing or oozing, also known as "hairy prints", is the name given for when small strings of filament are left on a printed model. This usually happens when the filament keeps flowing from the nozzle while the extruder is moving to another object. You can see this as a marginal line of filament left between the objects. This issue is caused by very high printing temperatures and/or using incorrect retraction settings" 2.

"Normally stringing shouldn't happen, however, it will sometimes happen depending on which filament you are using. PET-G is notorious for stringing, and hygroscopic materials such as TPU or Nylon may have stringing issues if they are not well-conditioned. There are many ways to fix stringing. Luckily, it's quite easy to solve. Let's look at all the variables that can influence stringing." 1.

-

Enabling retraction

- Retraction speed: 1200-6000 mm/min (20-100 mm/s)

- Retraction Distance: If you increase its value, it will reduce stringing, but if you increase it too much, your print will have gaps

-

Prime: This movement pushes the filament back in the nozzle exit so it can continue extruding

- Prime speed: If it's too fast, oozing will also occur at the start of the extrusion path, leaving behind a blob of filament.

-

Temperature is too high: try decreasing your extruder temperature by 5-10 degrees

-

Long movements over open spaces

-

Movement Speed: If your machine can handle moving at higher speeds, you may find that increasing these settings can also reduce stringing between parts.